As the owner or user of a commercial vehicle, you are required to develop and put in place systems for the regular inspection and maintenance of vehicles; there are two types of inspection which must be undertaken :

Here you will find information on what preventative maintenance is and how to determine how frequently vehicles should be subject to preventative maintenance.

Preventative maintenance consists of scheduled maintenance, component repairs and vehicle inspections carried out by a suitably qualified person to

Preventative maintenance doesn’t mean simply getting a bus, truck or trailer into the workshop and fixing what you see or doing a service on the vehicle. It means being on the look-out for things that might go wrong with the vehicle so that risks do not occur as a result of the deterioration or failure of a component or safety system on the vehicle. It is systematic detection, correction and prevention of failures before they become actual or major faults in contrast to corrective maintenance. Your preventative maintenance programme for each vehicle should be thorough, regular and frequent enough to meet the manufacturer's guidelines and that the vehicle, if used on a road, is safe and roadworthy. Pre-planned preventative maintenance along with daily walk around checks help ensure that vehicles are maintained in a roadworthy condition.

You may approach vehicle maintenance in a number of ways. It can be outsourced to third party providers, either in its entirety or elements of the maintenance task only. Or it may be undertaken in-house, by a suitably qualified person.

Whatever solution is adopted, if you own or use a commercial vehicle, you are responsible for having a proper preventative maintenance regime in place as well as being responsible for the roadworthiness condition of the vehicle including trailers being pulled on the road, even if you do not own that trailer.

You should schedule preventative maintenance at specific intervals so that you can identify a problem before it becomes a concern.

There are number of different factors to be considered when determining the frequency that a vehicle be subject to maintenance. Consideration should include the following :

There may be times when additional inspections may be necessary outside the routine pre-planned inspections, particularly if the vehicle is doing heavier work or travelling more than usual.

Some large fleet owners have opted to bring a sample of their fleet in for a voluntary safety test at a Commercial Vehicle Roadworthiness Test (CVRT) centre between inspection intervals. Depending on the condition of the vehicle as determined by the outcome of these inspections, fleet owners are adjusting the inspection intervals accordingly. Other factors that could determine the adequacy of inspection intervals is the pass/fail rate at the annual test, and in particular if there are any “Fail Dangerous” fail items.

When considering the appropriate frequency for your fleet, you should analyse your records and where components are regularly failing between inspections it would be appropriate to inspect these vehicles more often. All vehicles should be analysed separately as some may be used in different conditions than others; do higher mileage than others; be a different make, model, age etc.

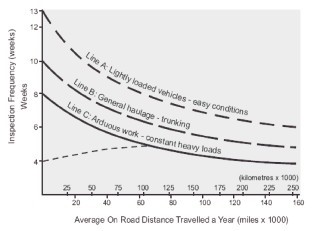

The table below shows indicative maintenance frequency in weekly increments. This table is a good guideline for new operators, however, experienced operators need to tailor their inspection intervals to suit the type of work they are engaged in and the characteristics of the fleet. The table is a guideline only and not intended to create legal minimums / maximums.

You should routinely review and make such changes as are required to ensure the effectiveness of your preventative maintenance system. Warning signals that your existing maintenance system is not effective include:

A bus operator has two buses: one bus operates between Galway and Dublin airport twice a day doing 200,000 kms each year and the second, smaller bus only does local runs totalling about 25,000 kms per year. The first bus is likely to need more frequent maintenance inspections, as it is doing far higher mileage. Using the earlier chart and assuming that the bus will operate under average conditions (Line B), the airport bus would have a maintenance inspection approximately every five weeks and the bus doing local runs would have a maintenance inspection approximately every nine weeks.

An experienced operator has tipper trucks in their fleet with an average annual mileage of 75,000km. Preventative maintenance intervals were scheduled for twice a year. These trucks operate both in the quarry and on the road. The operator found that costs were high for suspension and brake repairs. The operator decided to modify their maintenance schedule such that vehicles were inspected every 25,000km / 10 weeks, whichever came first. After trialling this for 6 months the operator noticed a decrease in repair costs.

A removal company with a mixed fleet of vans and trucks of various sizes initially used a 4 weekly inspection, however, they felt that this was too often and reduced the inspection frequency to 12 weekly. After a 6 month monitoring period, they saw a large rise in defects, and found that they had more on-the-road breakdowns. They decided to increase the inspection frequency to 6 weekly. After 12 months of monitoring, the defect level match what it was at 4 weeks and so the removal company decided to keep inspection frequency at 6 weekly.

A courier company with a fleet of trucks with weights of between 3.5t and 7.5t had an inspection interval of 13 weeks across the fleet. However, they found that vehicles operating between Galway and Donegal were having more downtime due to corrective maintenance than those operating locally in Galway city only. Therefore they amended their frequency schedule to every 10,000km or 6 weekly, whichever came first. They found that they inspected vehicles used for long journeys more often and the level of breakdowns was reduced.

A “Suitably Qualified Person”, is a nominated person given responsibility for carrying out inspection and maintenance of your vehicles and any repairs required to rectify defects on your vehicles or trailers.

Your SQP will usually be a mechanic or equivalent person with the relevant experience and/or qualifications to enable them to assess the roadworthiness of a vehicle and carry out any necessary repairs.